Here is our standard seals

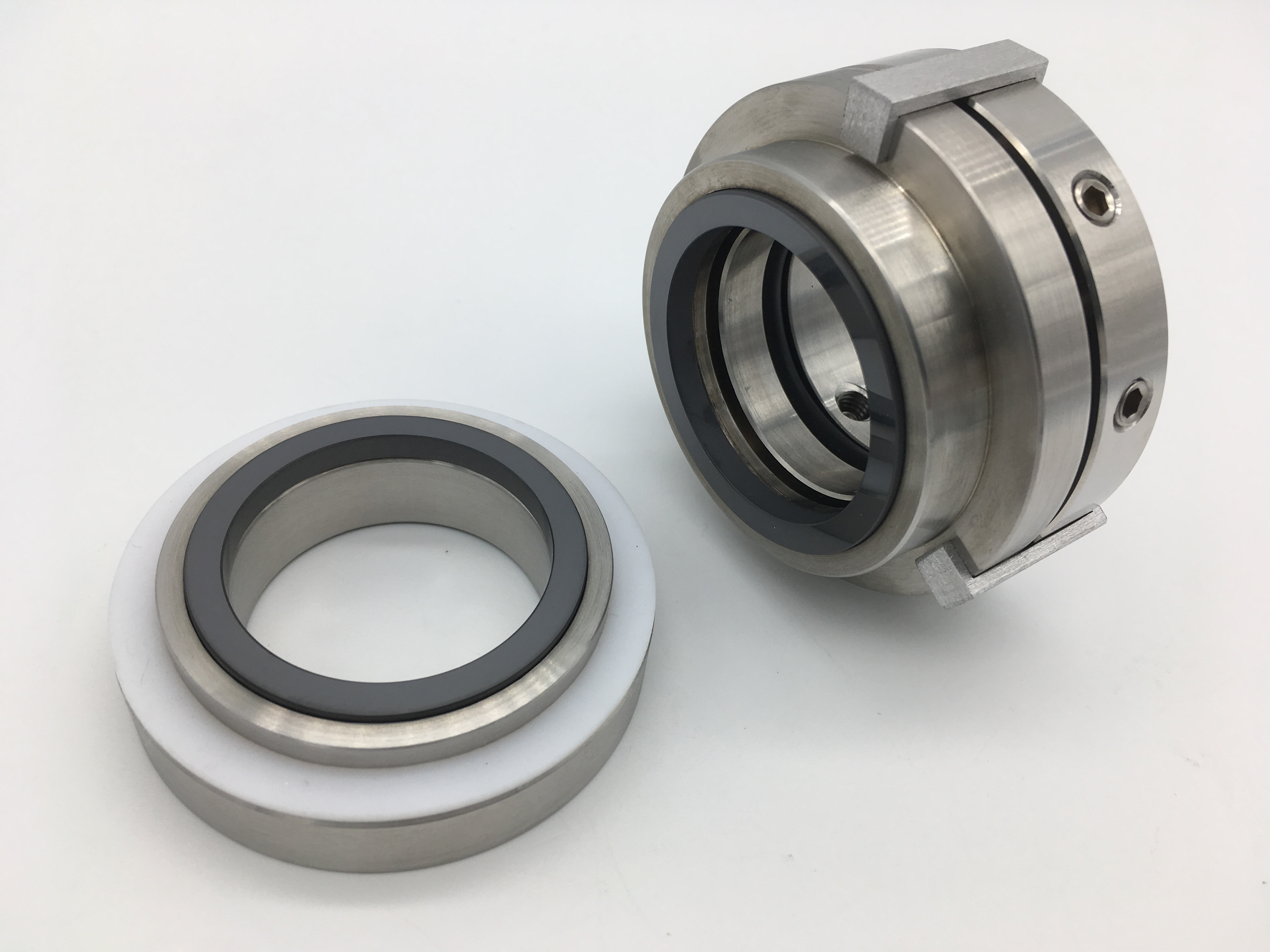

Component Seals

Type 20

- Unbalanced

- Single Coil Spring

- Setting-length of spring can be held inposition by built-in set ring and set

Type 30

- Unbalanced

- Single Coil Spring

- Rubber Bellows is designed incorporates in serveral functions, as seal face carrier, secondary sealing element, and drive collar.

- Independent of direction of rotation.

Type 33

- Unbalanced

- Conical Single Coil Spring

- Non-clogging single coil spring for dependability.

Type 35

- Unbalanced

- Single Coil Spring

- Shrink-fitted seal faces can be easily replaced with other materials.

Type 40

- Unbalanced

- O-ring secondary seal (standard)

- PTFE Wedge-ring secondary seal (optional)

- Multiple-spring exert even closing force on seal faces

- PTFE Wedge-ring secondary seal (optional)

- Shrink-fitted seal face scan be easily replaced with other materials.

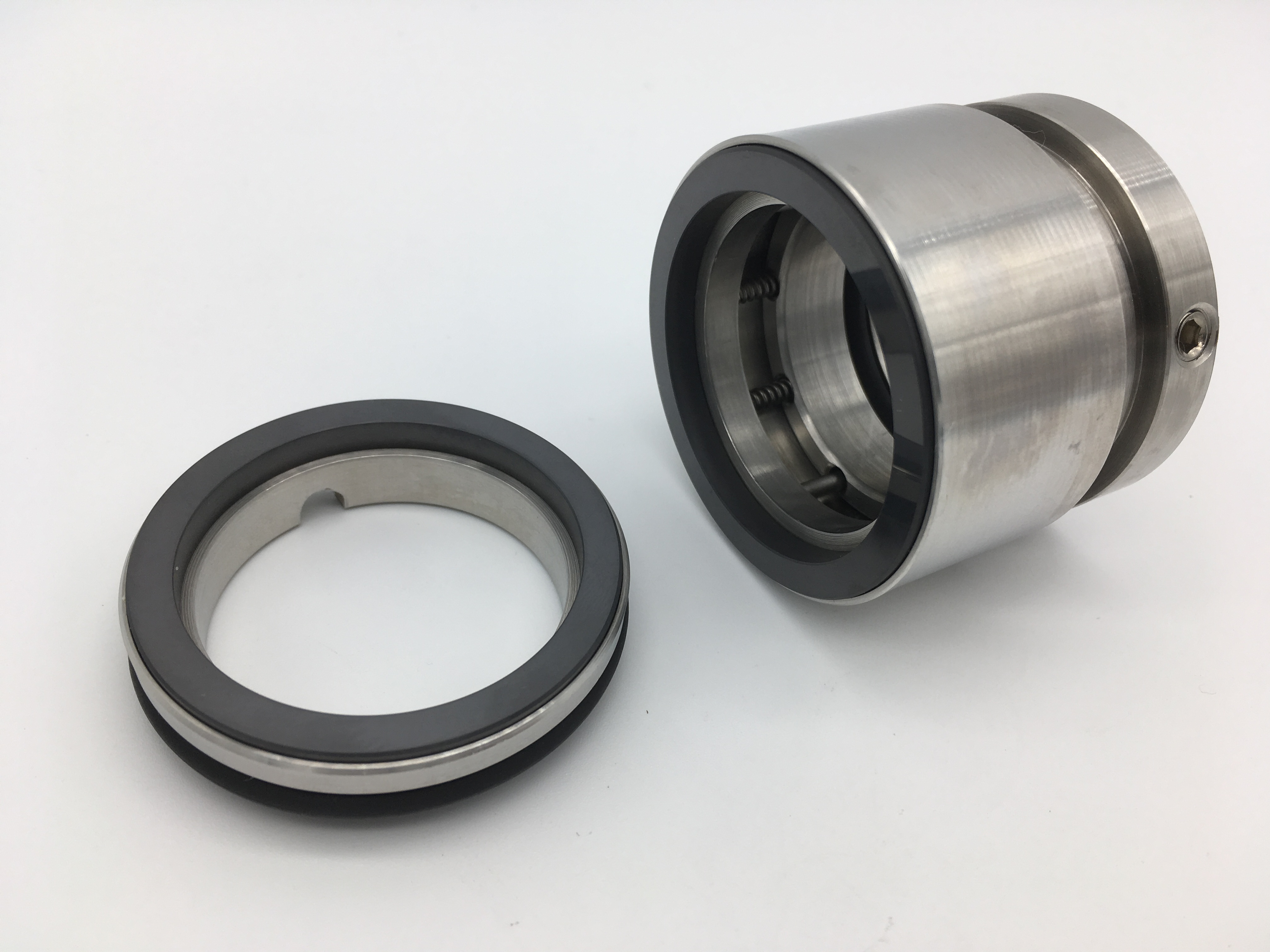

Type 50

- Unbalanced

- Single Coil Spring

- Positive-drive rotary part are designed for protecting slip of o-ring on shaft.

- Setting-length of spring can be held inposition by built-in set ring and set screws.

Type 60

- Unbalanced

- Multiple-Spring

- PTFE V-ring secondary seal (optional)

- Positive-drive rotary part are designed for protecting slip of o-ring on shaft.

- Shrink-fitted seal faces can be easily replaced with other materials.

Type 70

- Balanced

- Outside Installation

- Multiple spring exert even closing force on the seal faces.

- Set ring is provided for suitable operating length of rotary seal setting-length.

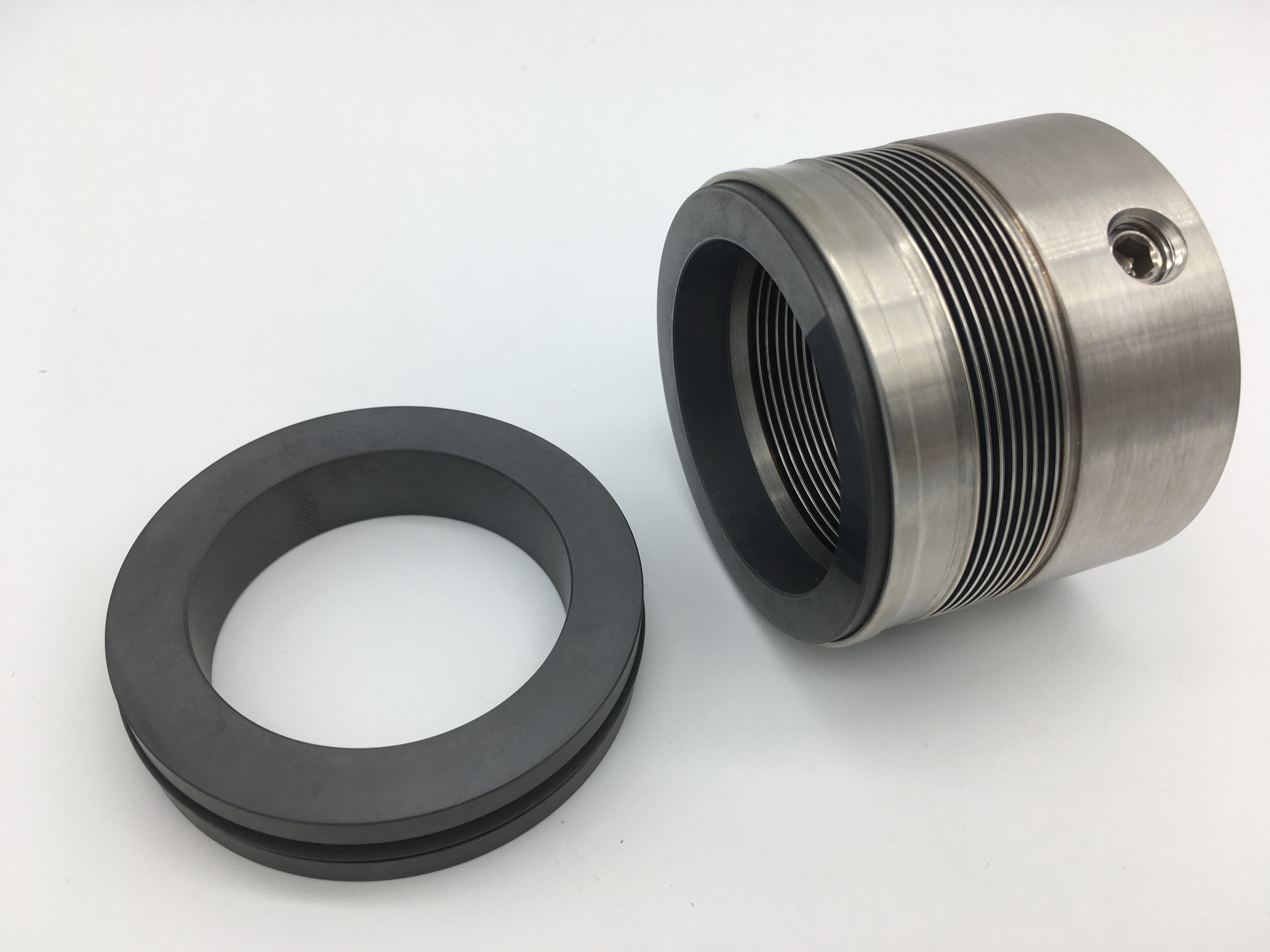

Type 80

- Balanced

- Metal bellows exert even closing force on the seal faces. Therefore, it is suitable for high speed rotation.

- Shrink-fitted seal faces can be easily replaced with other materials.

Type 100

- Balanced

- Springs are isolated from sealed liquid

- Setting-length is short

- Shrink-fitted seal faces can be easily replaced with other materials.

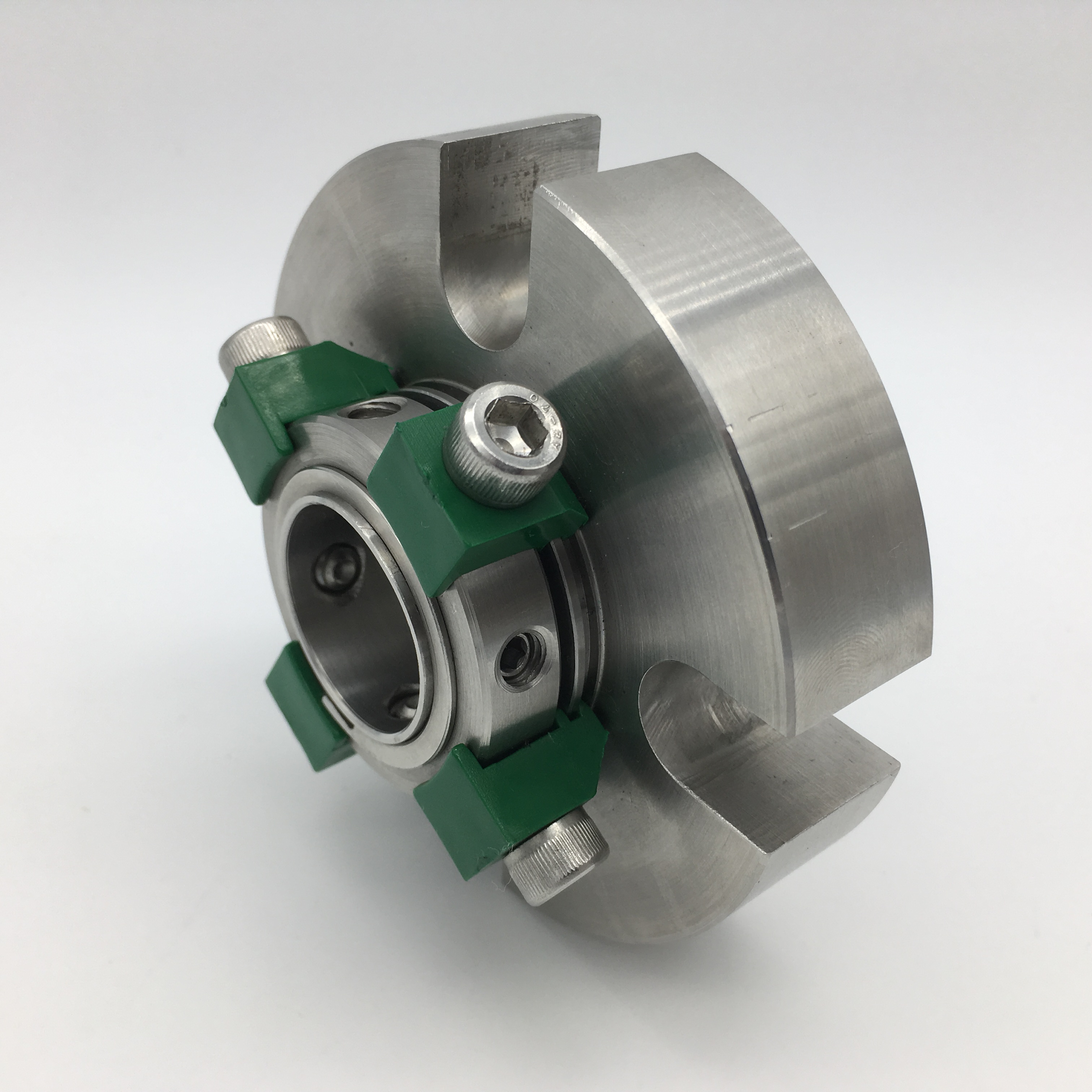

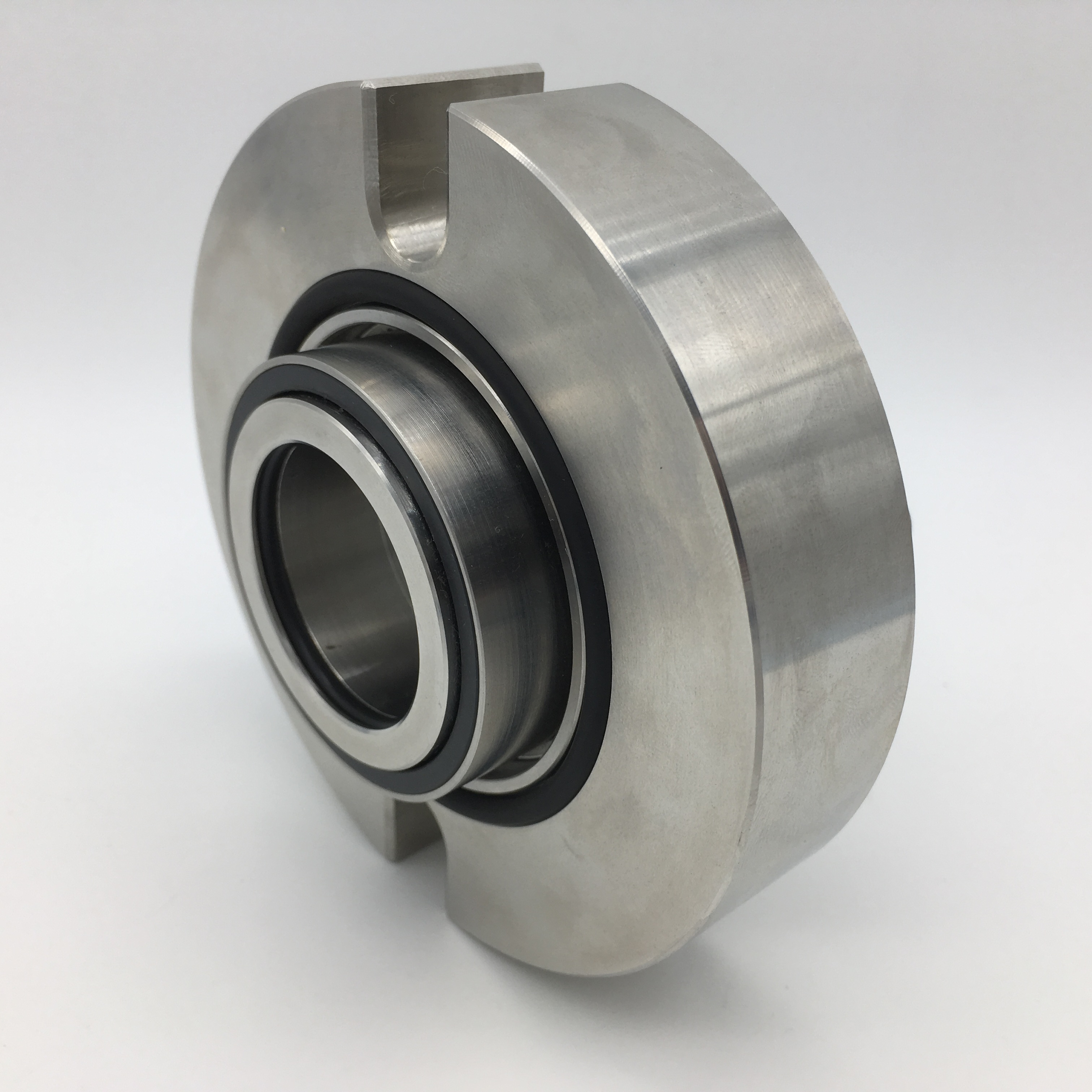

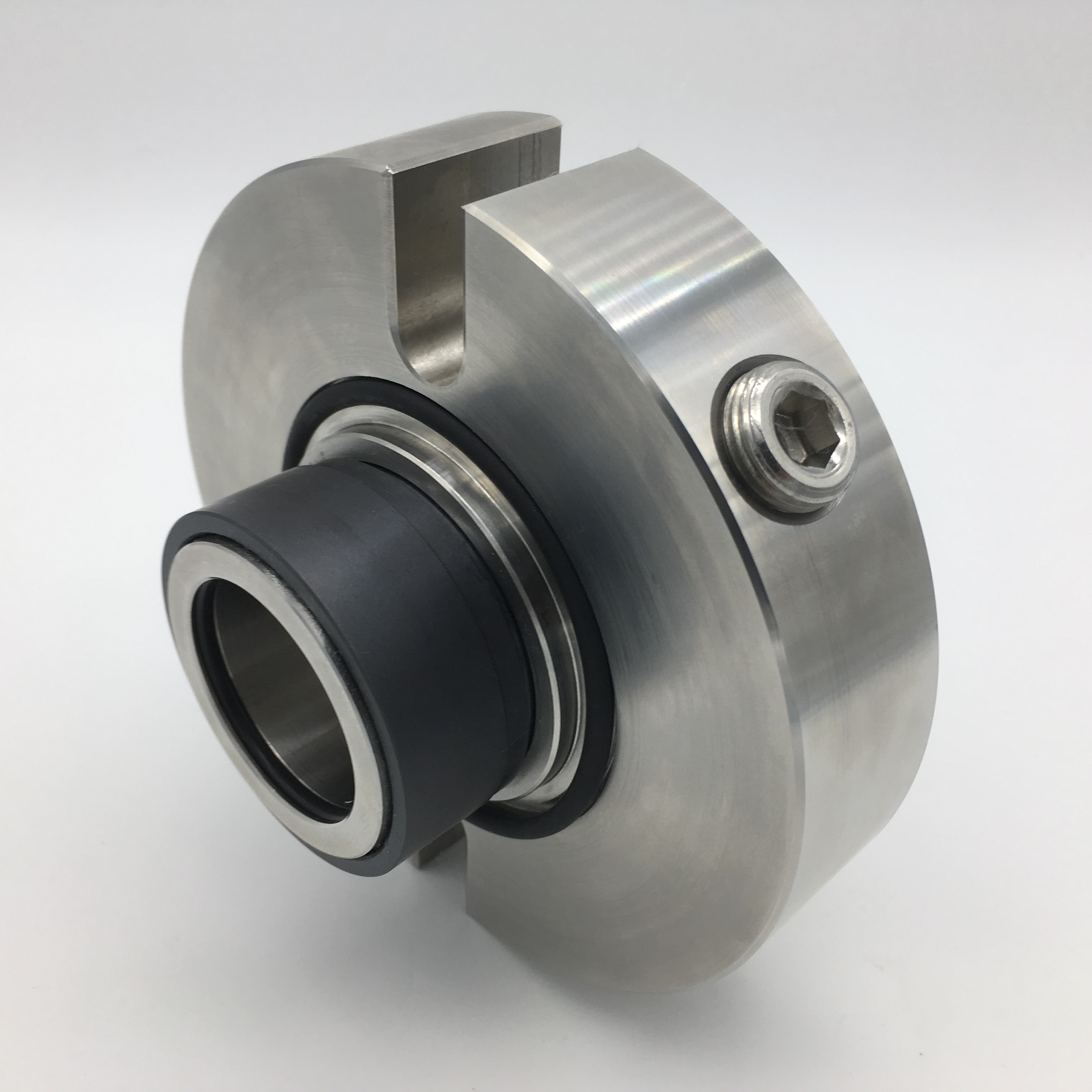

Cartridge Seals

Type 101

- Off-The-Shelf Availability

- Custom seals available in special alloys and sizes upon requests.

- Wide Temperature and Pressure Ranges.

- Cartridge design for precise, easy installation.

- Balanced design for wide range of services.

Type 111

- The balanced cartridge construction makes the suitable for a wide range of demanding applications.

- Due to the cartridge construction the seal can be easily installed.

- The springs of the seal are located in the stationary housing outside of the product.

- Premium-grade silicon carbide solid seal faces are excellent for high temperature ,high speed pumps and enduring abrasive fluid.

- Unique centralizing ring PTFE provided no setting clips to be removed or lost.

- No drive screw damage to shaft or sleeve.

Type 130

- Due to the cartridge construction the seal can be easily installed.

- The elastomer bellows seal designed for self-aligning feature compensates for excessive shaft end play and run-out.

- Non-clogging single coil spring for dependability.

- Independent of shaft rotating direction.

- A flushing fluid injected into the seal chamber for clean seal faces.

Type 150

- The balanced cartridge construction makes the suitable for a wide range of demanding applications.

- Due to the cartridge construction the seal can be easily installed.

- The springs of the seal are located in the stationary housing outside of the product.

- Premium grade silicon carbide solid seal faces are excellent for high temperature ,high speed pumps and enduring abrasive fluid.

- Unique centralizing ring PTFE provided no setting clips to be removed or lost.

- No drive screw damage to shaft or sleeve.

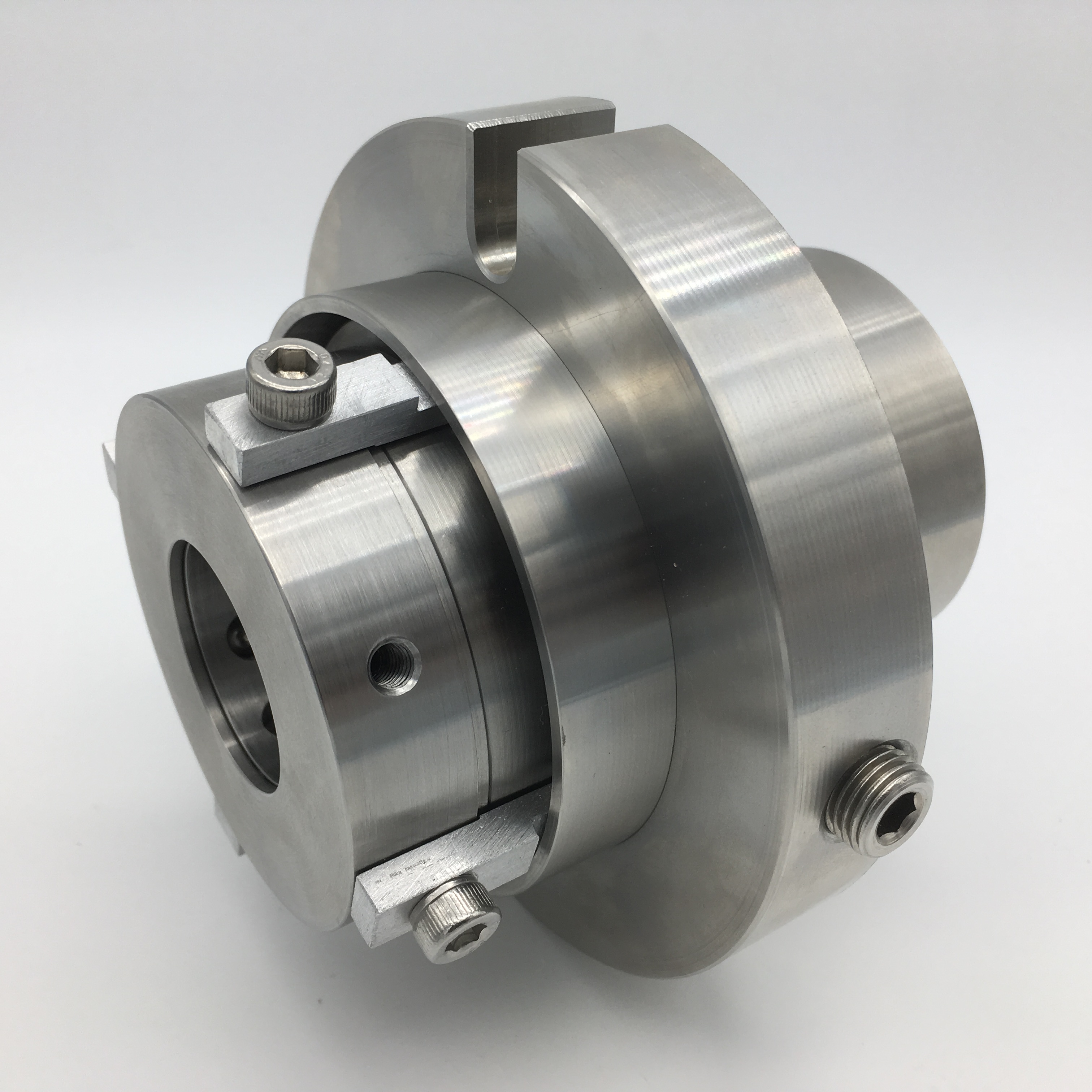

Type 201

- Off-The-Shelf Availability

- Custom seals available in special alloys upon request.

- Wide temperature and pressure ranges.

- Double balanced for wide range of operating conditions.

- Easy Installation

Type 211

- Due to the cartridge construction the sealcan be easily installed.

- The balanced cartridge construction makes the suitable for a wide range of demanding applications.

- A double balanced design is used to allow operation with pressurized or non-pressurized barrier fluid.

- The springs are isolated from the product to prevent clogging and corrosion.

Type 222

- The balanced cartridge construction makes the suitable for a wide range of demanding applications.

- Due to the cartridge construction the seal can be easily installed.

- The springs of the seal are located in the stationary housing outside of the product.

- Premium grade silicon carbide solid seal faces are excellent for high temperature ,high speed pumps and enduring abrasive fluid.

- No drive screw damage to shaft or sleeve.