Silicon carbide probably has the best resistance to corrosion in acids and alkalis of all advanced ceramic materials. It also has extreme hardness and high thermal conductivity and outstanding mechanical properties up to 1400°C.

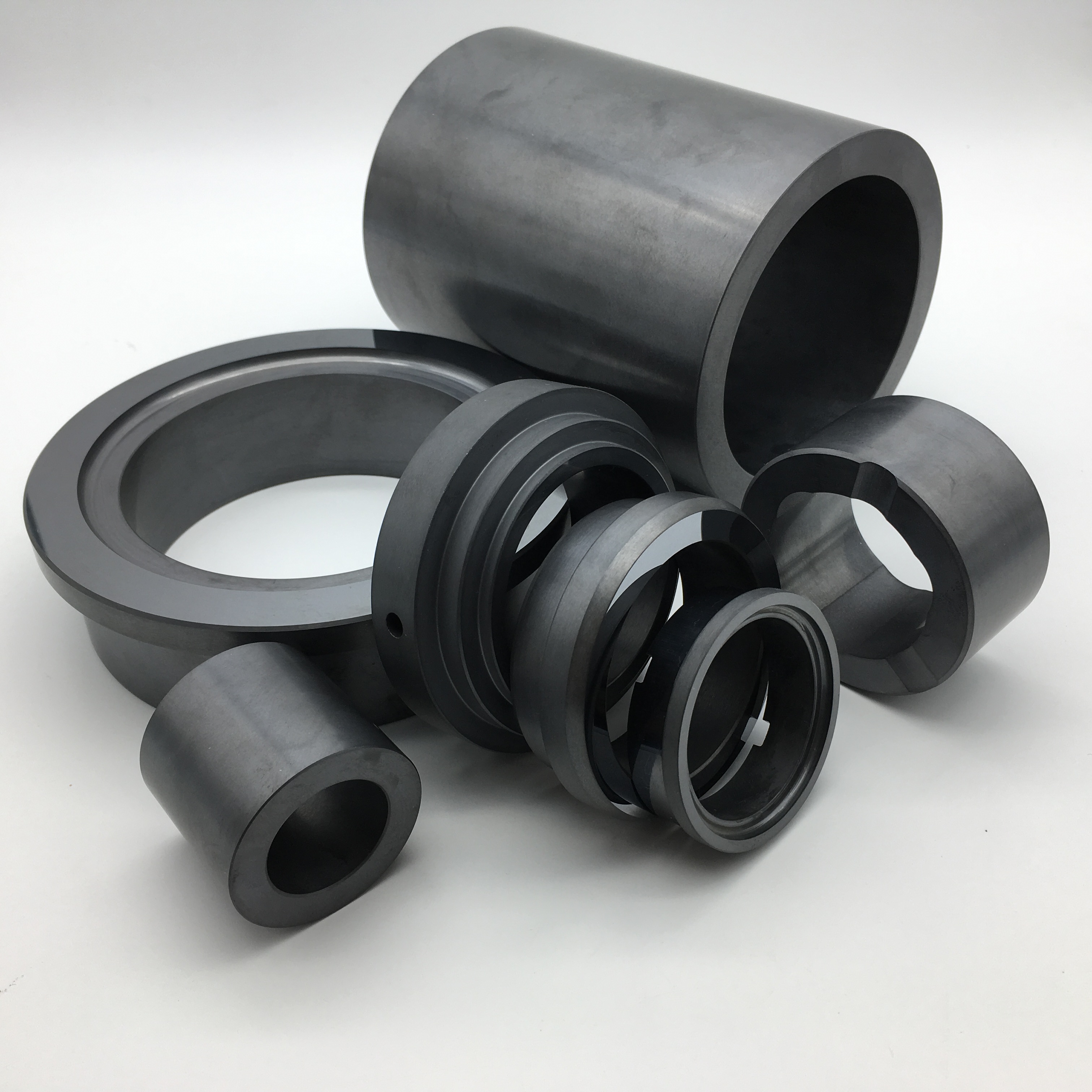

Silicon carbide ceramics have excellent wear resistance and are widely used as mechanical seals. The corrosion resistance ensures wide use in the Chemical Industry.

Typical Properties of Silicon Carbides

Sintered silicon Carbide (SiC) and reaction bonded silicon carbide combine excellent corrosion resistance with extreme hardness and high thermal conductivity.

Density (g/cm3) ~ 3.15

Flexural Strength (MPa) ~ 480

Elastic Modulus (GPa) ~ 410

Compressive Strength (MPa) ~ 3500

Thermal Conductivity (W/mK) ~ 150

Thermal Expansion (10-6/°C) ~ 4.4

Maximum Temperature (°C) ~ 1750

Hardness (Hv) ~ 2800

Density (g/cm3) ~ 3.10

Flexural Strength (MPa) ~ 462

Elastic Modulus (GPa) ~ 393

Compressive Strength (MPa) ~ 2700

Thermal Conductivity (W/mK) ~ 125

Thermal Expansion (10-6/°C) ~ 4.3

Maximum Temperature (°C) ~ 1400

Hardness (Hv) ~ 2500